Lithoman Machine Base | Pindar

Project Description

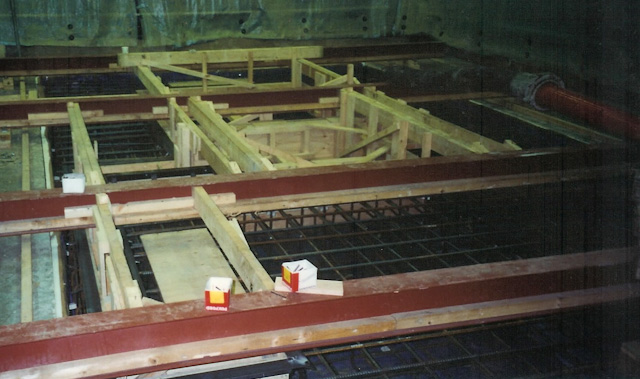

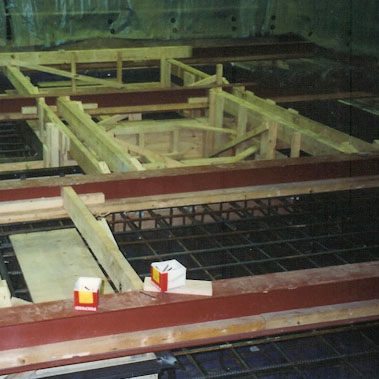

When it comes to specialist work then KFB (Scarborough) Ltd are without a doubt at the forefront of the industry, as was proved with this project. Pindar Printing required new machinery to be fitted within their factory therefore required new concrete beds to fit them on. This operation called for first class liaising with the client as the work had to be carried out whilst the factory was kept running. The excavations that were required had to be 40m long and 5.5m wide with depths varying from 700mm to 1.5m. The removal of the existing floor had to be done by cutting the concrete into squares and lifting them out to prevent vibrations that could affect the adjacent printing machinery. This was a very delicate operation as it was only six feet away from an already very busy printing machine that had to be kept running at all times. To give some idea of scale to this project, after the excavations were complete it required 20 tons of reinforcement steel, and 200 cubic metres of concrete, which equates to approximately 500 tons of concrete, to form the bed needed for the machine. Steel beams had to be used, and weighed down to stop the boxes (which created the pits) from floating when the concrete was poured all around them. The whole project reinforced the need to have a first class management team and a dedicated work force capable of working hand in hand with architects and engineers. The pit positions had to be accurate to ±3mm. A tough challenge!